- Languages:

- Blog

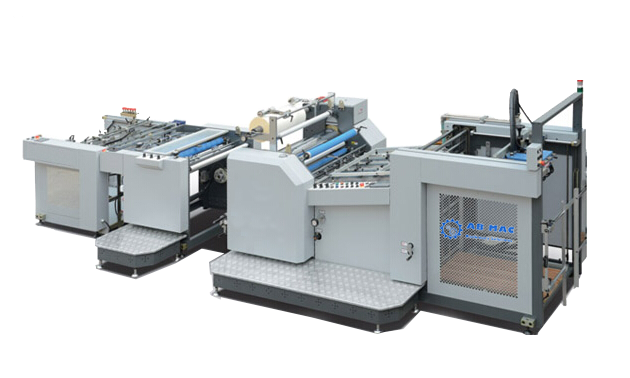

Automatic Double Side Laminator

Quick Overview

Fully Automatic Double Side Laminator save more for your double side lamination work. Feeding Unit by vacuum suction and start-from-top method by Oil-free vacuum pump; Touch Screen Interface, for easy operation;PLC control ; Hydraulic Press system is suitable for Thermal film as well as glueless film; Pneumatic air shaft used for film unwinding; Oil heating system, fast and efficient performance; Automatic Collection.

| Model | HP-FLD-1020 |

| Automation Grade | Fully Automatic |

| Application | BOPP thermal film, glueless film lamination on offset prints, digital prints, etc |

| Send an Enquiry |

Product Description

The double side laminating machine is composed of feeding system, laminating system and paper seperating system and paper collecting and temperature control system. Touch Screen HMI and programmable control (PLC) system. This machine centralizes the features of high automation, high precision of lamination, humanized configuration and easy operation, and is an excellent performance of equipment for the best choice of large and medium-size enterprises.

Product Highlights

- Automatic paper feeder adopts oil-free vacuum pump to feed paper automatically..

- Separating temperature control ensure the precision of double side lamination temperature.

- Hydaulic Pump supply high pressure to make possible to process any digital and standard thermal Laminating film available.

- Air expansion shaft releases film precisely, and also makes the loading and unloading of film roll more convenient.

- Paper receiving unit is furnished with not only automatic paper collector but also vibrating receiving table.

- Simple maintenance and fast part exchange.

- All Software and hardware manufactured by AB MAC.

- 7/24/365 Global service availabe.

Basic configuration

- Feeding unit

- Lamination unit - Double

- Perforating Knife

- Hydaulic unit

- Electrical and Pneumatic unit

- Collection Unit

| Max. nominal speed of lamination | 40m/min |

| Max. sheet dimensions | 800 x 1020mm |

| Min. sheet dimensions | 300 x 300mm |

| Paper Weight | 128 - 500gsm |

| Thickness of Thermal Film | 22 - 55 μm |

| Electrical Power | 3phase 380V, 37Kw Total |

| Dimension | 6200*1600*1900mm |

| Weight Total | 3600kg |

ES

ES عربية

عربية 中文

中文 Русский язык

Русский язык